Polishing and buffing are finishing processes for smoothing a workpiece’s surface using an abrasive and a work wheel or a leather strop.

Technically polishing refers to processes that use an abrasive that is glued to the work wheel, while buffing uses a loose abrasive applied to the work wheel.

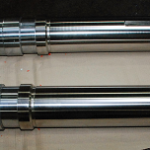

Polishing is a more aggressive process while buffing is less harsh, which leads to a smoother, brighter finish. A common misconception is that a polished surface has a mirror bright finish, however most mirror bright finishes are actually buffed.

Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes.

In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal’s microstructure under a microscope.

Silicon-based polishing pads or a diamond solution can be used in the polishing process. Polishing stainless steel can also increase the sanitary benefits of it.

The removal of oxidization (tarnish) from metal objects is accomplished using a metal polish or tarnish remover; this is also called polishing.

To prevent further unwanted oxidization, polished metal surfaces may be coated with wax, oil, or lacquer. This is of particular concern for copper alloy products such as brass and bronze.

Take a look at our other services:

Bead Blasting

Click to View

Hard Chrome

Click to View

Electroless Nickel

Click to View

Zinc Plating

Click to View