Yorkshire Plating Services

The service we offer complies with the latest legislation for RoHS and WEEE compliance. This also meets with the oil industries corrosion resistance requirements.

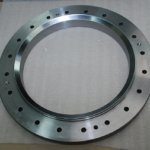

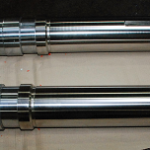

The Electroless nickel coatings have many fantastic properties. The metal layer deposited by the electroless nickel process has an even thickness to all surfaces of the component, virtually regardless of its shape.

This uniform coating is the perfect solution for critical high-end engineering items such as those used in the defence, healthcare, automotive and aerospace industries.

Electroless Nickel is extremely resistant to corrosion and will therefore extend the life of everything it coats. Electroless Nickel also prevents the formation of rust on components, this in turn stops the part becoming a catalyst for rust on surrounding parts.

This makes it ideal for coating components exposed to harsh environments such as those operating in the marine, oil and gas and defence industries, it can also reduce the cost of repair and replacement parts.

It achieves excellent hardness and wear resistance results. The coating provides a smooth whitish semi-bright deposit and has very good corrosion resistance, it is also ideal where friction and wear are issues, when used with the appropriate heat treatment, Electroless Nickel can be hardened up to 950vhn.

It is used in many different areas from food services, machinery, aerospace and tools, the list is almost endless.

Other advantages of Electroless Nickel Plating include:

For more details please do not hesitate to contact us.

© 2024 Yorkshire Plating Services. Designed and Built by PRS Printers